Just 48 hours.

That’s how long it took Pat Dubreuil to assemble a team of businesspeople to develop a concept for a decontamination pod for personal protective equipment (PPE) being used in the fight against COVID-19.

Now the Sudbury entrepreneur is seeking the financing to make it happen.

The Mobile Decontamination-POD (or Decon-POD) is a joint effort by Dubreuil, the owner of Let’s Roll 'Ideation' Consulting, André Dumais of Ionic Mechatronics, Dr. Dennis Reich at Synaptic Technologies, and Christian Lanas of CL Mining Consulting.

Together, the group has come up with the idea for a mobile bio-decontamination chamber that would decontaminate PPE, allowing masks, gowns, and other equipment to be reused as many as 30 to 50 times before degradation of equipment starts to take place.

Dubreuil said he took his inspiration from a 2016 Duke University proposal in which researchers at the American college put forward the idea of a decontamination room that could be built within a hospital.

But to better serve Northern Ontario, Dubreuil is championing the idea of a mobile unit, which could be easily relocated depending on where the need is most.

“We need to drop this in the hospital parking lot and service their gear, because they need every room they have in that hospital. It's already at capacity,” he said. “We can't start taking away rooms for this type of purpose.

“Kapuskasing is in need, and Sault Ste. Marie is in need, and a lot of Northern Ontario hospitals would require this service.”

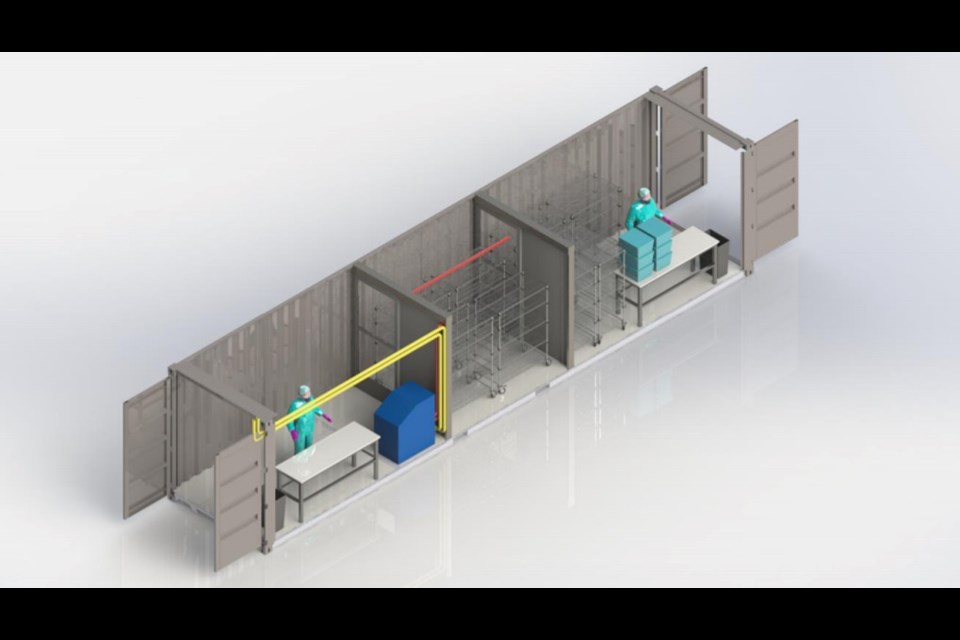

Built from a shipping container, the Decon-POD uses vaporized hydrogen peroxide (VHP) to decontaminate the PPE.

Contaminated equipment is put into the pod’s “dirty room” from one end before being exposed to VHP, which is non-toxic and destroys the full spectrum of biological contaminants.

Once clean, the sterilized PPE is then removed from the “clean room” on the other end of the pod.

The entire process takes between two and four hours.

Want to read more stories about business in the North? Subscribe to our newsletter.

Dubreuil estimates, when looking at something like N95 masks, up to 1,000 could be sterilized at one time.

As part of the process, facilities would have to keep track of the PPE and how effective it remains after use, Dubreuil said.

So, for example, ear straps on masks that have lost their elasticity would be discarded because the protection of health-care workers would no longer be guaranteed.

“So there's a collection process, and then there's a decontamination process, and then there's a reservicing process that needs to be part of this solution," he said.

At this point, the procedure is experimental, and it would have to receive approval from Health Canada in order to go forward.

But, on April 7, Health Canada indicated it was working on expediting regulatory approvals for the manufacture of equipment related to COVID-19.

Depending on support for the project, Dubreuil said one or more of the Decon-PODs could be built and situated around the North, serving long-term care homes, seniors’ residences, hospitals, first responders – anywhere people are facing a risk.

“There's all kinds of people that are exposed, and they need to replenish this PPE.”

In addition to solving the problem of equipment shortage, Dubreuil said this addresses concerns about interruption to supply chains, and helps stem the amount of waste going into the landfills.

“Once you have your supply, you basically recycle this stuff,” he said. “So then it takes a lot of pressure off the whole distribution system and making sure there's an adequate supply."

The team has submitted their idea to the US$1-million Vale COVID-19 Challenge, which the Brazilian mining giant issued on April 3 to help generate innovative commercial solutions to combat the spread of the novel coronavirus.

The submission period for the contest closes April 9.

But even if the concept is successful, Dubreuil is concerned it could take too long to get the Decon-POD to market, and so the team is exploring other options to raise the $250,000 required to build the unit, including a GoFundMe crowdfunding campaign, which has now been launched.

“We want to help Northern Ontario, but we need help,” he said.

The vaporizer alone runs about $80,000, he said, and then the unit has to be modified to meet specifications, including a special coating on the inner chamber and sealing the unit to be completely airtight.

The good news is that all of the components are available right in Ontario, and Dubreuil has already figured out lead times and costing.

If the team can make a go of it, Dubreuil said they want to share the concept with any other community that needs it.

“Should we be successful with this, we'll open source some of the IP (intellectual property) that we've put into this, so that other people can reproduce it,” he said.

“If somebody in India was to reproduce this, we'll make it available. It's all about helping. It's not about making money.”