Tyler Bragnalo wasn’t sure how he would adjust to working in a post-secondary environment.

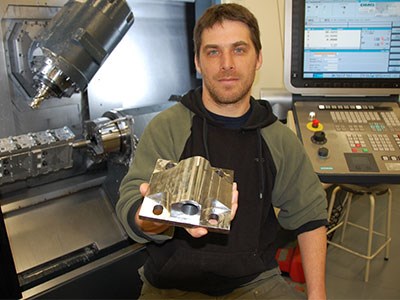

The owner of Kam Valley Industries had moved lock, stock and lathe to Confederation College last year to run his machining and design business, but also oversee its new advanced manufacturing lab.

“I thought it would be a pain in the butt,” said Bragnalo of mentoring college students and working hand-in-hand with a not-for-profit organization in the Northwestern Ontario Innovation Centre.

“I have to run a business and to have a bunch of people take up your time that aren’t producing….but I’m actually shocked and all these fears proved to be unfounded.”

Mi-Zone –Makers and Innovators – is a collaborative venture between Kam Valley, the Innovation Centre and Confederation College. The sophisticated machine shop is a doors-open facility to assist small manufacturers and local inventors bring their ideas to the design and prototype phase, and eventually into the commercial production stage.

“I was skeptical at first in how these guys fit in, but it’s been awesome.”

Bragnalo is working with multi-media production students who specialize in 3-D CAD visualization and animation techniques often used in the entertainment industry. “We use 3-D CAD for our industry. And these two streams never cross.”

Bragnalo has recruited a Confederation aerospace manufacturing student to add to his three-employee firm. “We’re trying to convince him to stay on once he graduates.”

After working out of a cold and drafty space at the former Hillcrest High School, Bragnalo was lured over to the campus and moved into a 3,500-square-foot shop in the McIntyre Building, the home of Confederation’s engineering technology programs.

He began prepping the shop last May to move in the CNC milling equipment, lathes, welding stations and other equipment.

More modern technology will be moved in over the next few months, but the cornerstone of Mi-Zone is its top-of-the-line mill-turning centre, a DMG CTX-beta 1250.

“It’s a super complex machine, there are not many of them out there so each one is basically custom,” said Bragnalo.

The machine is capable of long production runs of intricate parts and also one-off, specialized prototype work.

“Parts that would take seven operations (on a conventional milling machine) can be done in a single operation.”

Bragnalo is working on his own company’s projects as well as serving Innovation Centre clients.

He’s worked with Cinevate, a Thunder Bay film equipment company, the Thunder Bay Regional Research Institute, and has helped a heavy trailer refurbisher perfect a new air-ride suspension system for a trial with Ford Motor Company.

The lab has been set up with a $500,000 contribution from the Northern Ontario Heritage Fund and $390,000 from FedNor.

Bragnalo said the goal of Mi-Zone wasn’t to create something that could directly compete against other manufacturers in the region, but rather assist them in bidding on large projects and possibly allowing them to outsource specialized parts that they can’t necessarily do in-house.

“I’m trying to turn this into the opposite of conflict. Here’s a resource that few can afford and no one has. Rather than steal their work, we want this to be a test facility for them.

“We specifically sourced equipment that no one else had and we wouldn’t be in a position to push clients away from existing (manufacturers). That’s not what we are.”

Bragnalo believes the lab offers a vehicle to galvanize the North’s manufacturing capacity, rather than continue to have companies working in silos.

“I figure collaboration is much productive than competition.”

How Mi-Zone will evolve is uncertain, said Bragnalo, but the wheels are turning.

“Whatever we bring, it’s got to be something we know the region needs.”

He’ll leave that blue-sky thinking to Innovation Centre manager Judy Sander, college president Jim Madder and FedNor technology officer Mike Belliveau.

“All these people had the bigger vision than I had and they brought me to the light, and I totally get it. I see the impacts, I see the benefits, I’m sold on it.”